How Does Enhanced Thermal Conductivity ins...

In the unexpectedly evolving landscape of the automobile industry, the shift in the direction of sustainable mobility has caused the sizeabl...

Information to be updated

Information to be updated

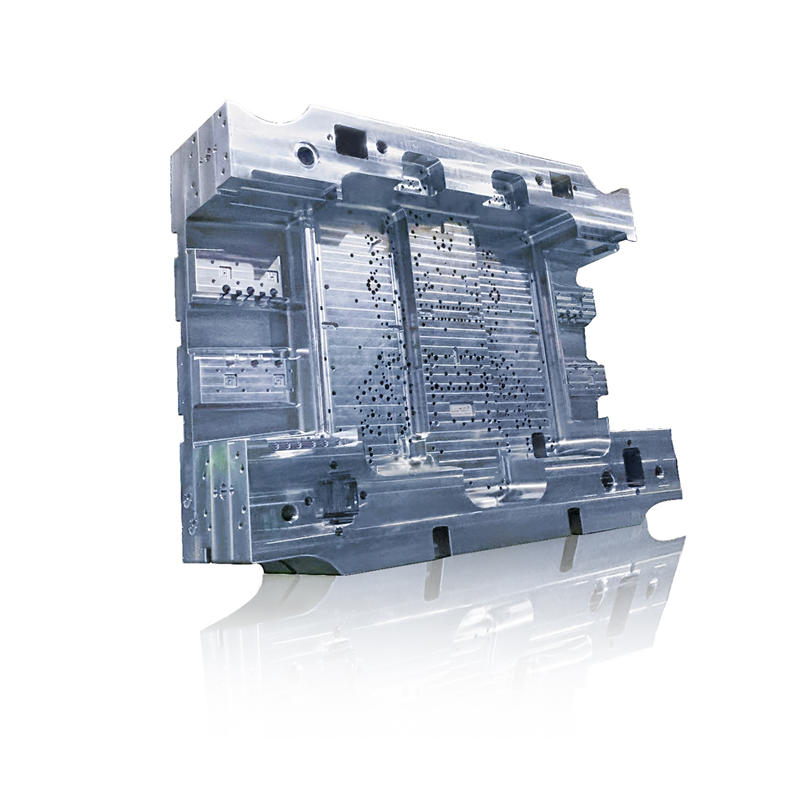

Kejia (Changxing) Mold Base Manufacturing Co., Ltd. (formerly known as Jiayou Mold Material Co., Ltd.) was established in 1983, with a history of 38 years. It is located in the national high-tech development zone of Taihu Street, Changxing County, Huzhou City, covering an area of 100 acres, with a new factory building and office space of 100,000 square meters. The total investment of the project is 560 million yuan. Now we have introduced CNC machining center, CNC deep hole drilling, sawing machine, CMM, 200-ton crane, mold turning machine and other production and auxiliary equipment. After the completion of the project, the production capacity of the mold base production line with an annual output of 3,000 sets will be formed. With more than 400 employees, it is a joint-stock enterprise specializing in the sale of mold steel and mold bases.

In the unexpectedly evolving landscape of the automobile industry, the shift in the direction of sustainable mobility has caused the sizeabl...

How does the implementation of a one-piece die-forged body structure make contributions to the reduced weight of the new strength vehicle re...

In the context of recent strength automobile rear warehouse molds offering a one-piece die-forged body shape, how does the incorporation of ...

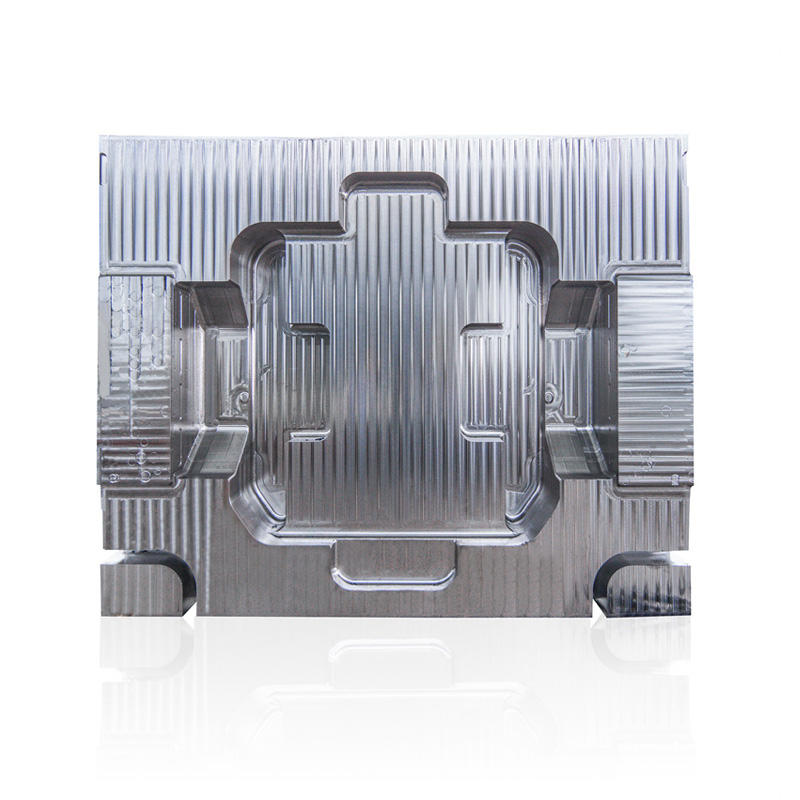

Application of Injection Mold Base

Injection Mold Base is a process used to produce parts made of plastic or other materials by melting the raw material and injecting it into a mold. The base of an injection mold is a critical component of the molding process, as it provides structural support for the mold and helps to secure it in place during the molding operation. The base of an injection mold can be made from various materials, including steel, aluminum, or composite materials, and is typically designed to meet specific requirements based on the size, shape, and material of the parts being produced. The base of an injection mold also has features such as waterlines, vents, and ejector pin locations that help to ensure the quality and consistency of the molded parts.The Injection Mold Base has several key characteristics that are important for its performance and functionality:

Material: The base material can be steel, aluminum, or composite materials. The choice of material will depend on factors such as the size, complexity, and production volume of the parts being produced.

Strength and durability: The base must be strong enough to withstand the high pressure and temperature involved in the molding process, as well as the repeated cycles of opening and closing the mold.

Precision: The base must have high dimensional accuracy and consistency, as any deviations will affect the quality of the molded parts.

Surface finish: The surface of the base should have a smooth and uniform finish to ensure the molded parts release easily from the mold and have a high-quality appearance.

Ejection system: The base must have a mechanism for removing the molded parts from the mold, such as ejector pins or stripper plates.

Cooling system: The base must have a cooling system, such as water lines, to regulate the temperature of the mold and ensure that the molded parts have a consistent and uniform temperature profile.

Maintenance: The base must be designed for easy maintenance and repair to minimize downtime and maximize production efficiency.

Please complete the form below and our team will get back to you as soon as possible.