How Does Enhanced Thermal Conductivity ins...

In the unexpectedly evolving landscape of the automobile industry, the shift in the direction of sustainable mobility has caused the sizeabl...

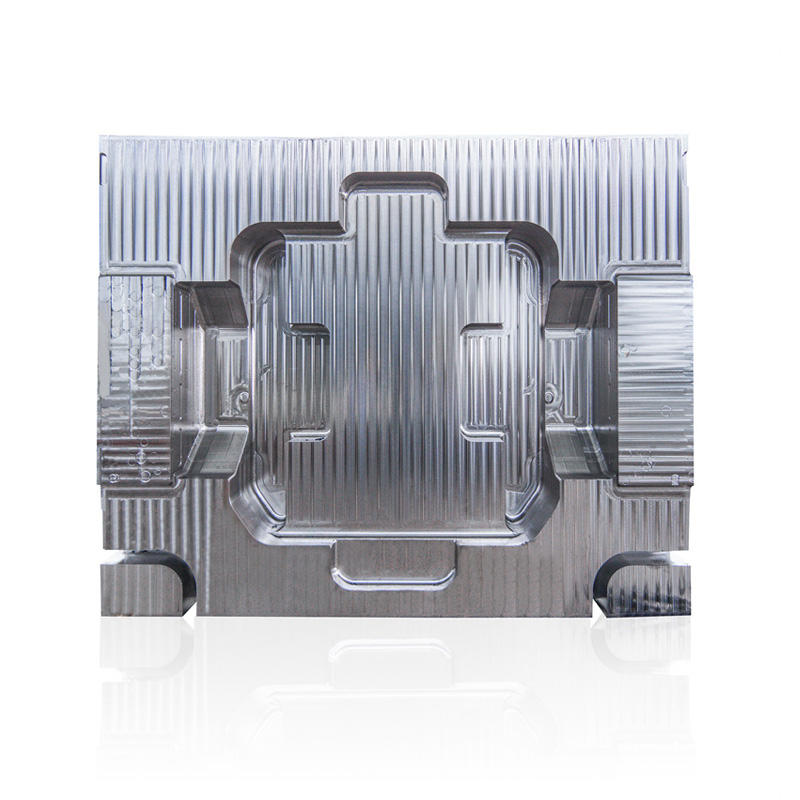

Product Description: Alloy molding frames of three-cylinder engines of fuel cars are frames made of ...

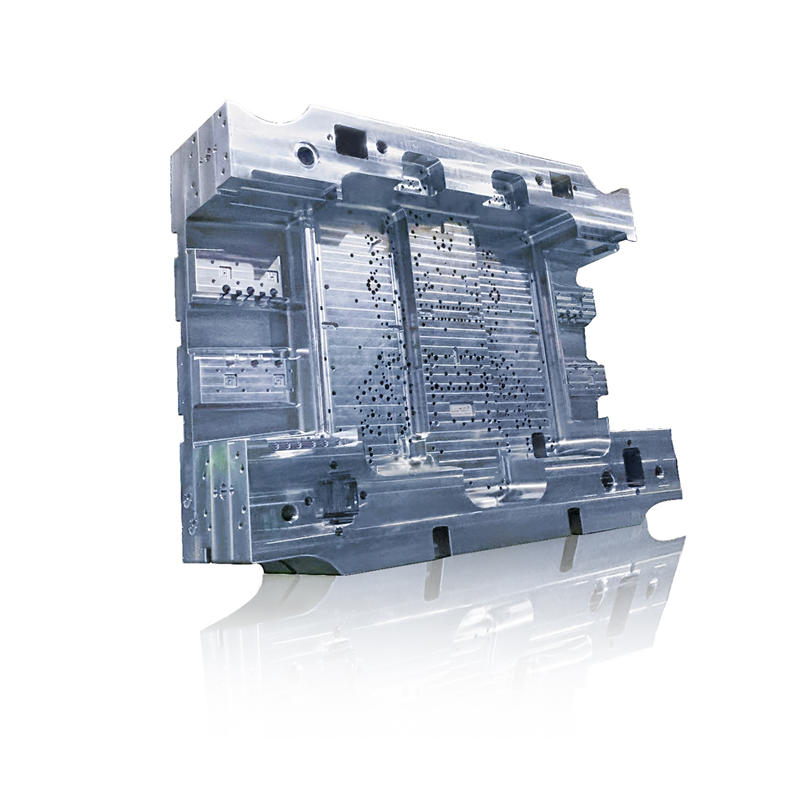

Product Description: The mold frame for the rear warehouse left and right structural parts of a new ...

Product Description: At the core of our manufacturing process lies a formidable die casting machine ...

Product Description: A slider seat is a component commonly found in vehicles, particularly in automo...

Product Description: A "new energy vehicle rear compartment mold" refers to the tooling or mold used...

Product Description: In the manufacturing process of automotive seats, including those in electric c...

Kejia (Changxing) Mold Base Manufacturing Co., Ltd. (formerly known as Jiayou Mold Material Co., Ltd.) was established in 1983, with a history of 38 years. It is located in the national high-tech development zone of Taihu Street, Changxing County, Huzhou City, covering an area of 100 acres, with a new factory building and office space of 100,000 square meters. The total investment of the project is 560 million yuan. Now we have introduced CNC machining center, CNC deep hole drilling, sawing machine, CMM, 200-ton crane, mold turning machine and other production and auxiliary equipment. After the completion of the project, the production capacity of the mold base production line with an annual output of 3,000 sets will be formed. With more than 400 employees, it is a joint-stock enterprise specializing in the sale of mold steel and mold bases.

In the unexpectedly evolving landscape of the automobile industry, the shift in the direction of sustainable mobility has caused the sizeabl...

How does the implementation of a one-piece die-forged body structure make contributions to the reduced weight of the new strength vehicle re...

In the context of recent strength automobile rear warehouse molds offering a one-piece die-forged body shape, how does the incorporation of ...

The features of Die Casting Mold Bases typically include the:

High strength and rigidity to withstand high-pressure casting.

High dimensional accuracy and stability to ensure consistent product quality.

Good thermal conductivity to distribute heat evenly and reduce thermal stress.

Corrosion resistance to withstand harsh working environments.

Ease of maintenance for quick and efficient repairs.

Customizability to meet specific mold design requirements.

Compatibility with various die-casting processes, such as hot chamber and cold chamber.

Durability and long service life to minimize downtime and improve cost-effectiveness.

Application of Die Casting Mold Base

Die Casting Mold Bases are used in the die-casting process, a manufacturing method that involves injecting molten metal into a mold under high pressure to produce precise, complex-shaped parts. The mold base provides the structure and support for the mold cavity and ensures the stability of the casting process.

Die-casting mold bases are widely used in various industries, including automotive, aerospace, electrical, and consumer goods. They are used to produce a wide range of products, such as engine components, structural parts, electrical housings, and consumer goods like toys, tools, and appliances.

The use of die-casting mold bases allows for high production efficiency, consistent product quality, and reduced production costs, making it a popular choice for the mass production of high-precision metal parts.

Please complete the form below and our team will get back to you as soon as possible.